When a Pipeline Manufacturer improves long-term infrastructure success

Checking Out the Leading Pipeline Manufacturers: Quality, Dependability, and Innovation

The pipeline manufacturing market stands at the crossway of top quality, development, and integrity, driven by leading firms such as Tenaris and Vallourec. These suppliers are not only devoted to generating high-performance materials however are likewise pioneering lasting techniques that address modern-day ecological concerns. As we check out the requirements that define quality in pipeline services, it comes to be noticeable that the landscape is rapidly developing. What specific technologies are emerging, and how are these innovations forming the future of pipeline infrastructure? The responses may redefine sector standards in means that are not yet completely recognized.

Leading Manufacturers Summary

In the domain name of pipeline manufacturing, numerous key players emerge as leaders, each adding substantially to the industry's landscape. Companies such as Tenaris, Vallourec, and JFE Steel have actually established themselves as frontrunners by constantly providing top quality products that meet rigorous sector requirements. Tenaris, renowned for its innovative remedies, focuses on smooth and bonded pipes, providing primarily to the oil and gas sector. Vallourec, a French multinational, concentrates on the production of premium tubular services, emphasizing sustainability and advanced technology in its manufacturing processes.

JFE Steel, a significant Japanese manufacturer, is recognized for its comprehensive array of steel pipelines, particularly those used in power and facilities jobs. Their dedication to research and development has actually allowed them to generate high-performance products that stand up to extreme ecological problems. Furthermore, firms like united state Steel and National Oilwell Varco have expanded their market visibility by expanding their product offerings and enhancing operational performances.

These leading makers not only dominate the market yet also drive advancement within the industry, establishing criteria for quality and reliability that various other gamers desire achieve. Their payments are crucial for meeting the increasing need for effective and resilient pipeline remedies worldwide.

Requirements for Quality Assessment

Quality assessment in pipeline manufacturing pivots on 2 critical requirements: product resilience criteria and making procedure efficiency. Guaranteeing that materials fulfill strenuous toughness criteria is important for the long life and dependability of pipes. Furthermore, optimizing the manufacturing procedure can enhance productivity while preserving premium quality, eventually influencing overall efficiency and security.

Material Durability Requirements

Assuring the long life and reliability of pipeline materials is important for maintaining facilities honesty and operational efficiency. Material longevity requirements play an essential role in examining the top quality of pipelines, dictating the efficiency and lifespan of the products utilized in building. Manufacturers have to abide by a variety of strenuous standards, consisting of those established by organizations such as ASTM International and the American Oil Institute (API)

These criteria examine numerous aspects, consisting of corrosion resistance, tensile stamina, and exhaustion efficiency. For example, pipes used in destructive settings need materials that can hold up against chemical degradation, while those based on high-pressure conditions must show exceptional tensile stamina.

Furthermore, elements such as temperature level variations and environmental problems should be thought about, as these can considerably influence product actions with time. Manufacturers often make use of advanced testing approaches, including sped up aging tests, to mimic long-lasting wear and guarantee that materials fulfill or go beyond market criteria.

Manufacturing Process Performance

Manufacturers' capability to maximize making process efficiency is essential for producing top notch pipes that fulfill stringent market standards. Performance in making straight influences expense monitoring, manufacturing timelines, and total item stability. To attain this, leading pipeline suppliers implement innovative methods such as lean manufacturing, automation, and real-time data analytics.

Lean manufacturing concepts are necessary in minimizing waste and maximizing source application. By improving processes and getting rid of redundancies, producers can boost efficiency while guaranteeing consistent top quality. Automation technologies, including robotics and computer mathematical control (CNC) machines, play an essential role in boosting accuracy and minimizing human mistake, thus boosting the integrity of the last item.

In addition, the usage of real-time data analytics allows manufacturers to keep track of manufacturing processes continuously, enabling them to recognize traffic jams and make timely adjustments. This aggressive technique not just boosts effectiveness yet likewise supports quality control procedures by guaranteeing conformity with regulative standards.

Dependability in Pipeline Solutions

Reliability in pipeline remedies is critical, as it directly influences the safety and performance of fluid transport systems. Trick variables consist of the toughness of products made use of, adherence to strenuous testing and accreditation standards, and the unification of ingenious material solutions that enhance performance. Comprehending these elements is vital for manufacturers aiming to provide trustworthy pipeline framework.

Value of Sturdiness

Accomplishing toughness in pipeline services is important, as it directly impacts the long-term performance and safety and security of framework. Long lasting pipelines are necessary for decreasing maintenance expenses and decreasing the chance of tragic failings. This integrity is especially essential in markets such as oil and gas, water supply, and wastewater administration, where the repercussions of pipeline failure can be severe, both economically and environmentally.

The materials and manufacturing processes used by pipeline makers play a substantial role in identifying the longevity of the end product. Making use of top quality raw materials, advanced technologies, and ingenious layout concepts guarantees that pipes can endure numerous stress factors, including pressure changes, temperature variations, and corrosive settings.

The resilience of pipes is closely linked to their ability to stand up to outside factors such as soil motion, seismic activity, and chemical direct exposures. Reliable rust security techniques, such as finishes and cathodic protection, better improve the longevity of pipelines, safeguarding them versus degeneration in time.

Purchasing durable pipeline services inevitably converts to increased operational performance, lowered downtime, and enhanced safety, affirming the vital relevance of toughness in modern-day pipeline manufacturing.

Evaluating and Certification Standards

In the domain name of pipeline remedies, extensive screening and certification criteria are important to ensure the reliability and security of infrastructure. These criteria offer as benchmarks for assessing the efficiency and resilience of pipeline products and systems, confirming they satisfy certain governing and industry demands.

Testing processes normally encompass numerous techniques, including pressure testing, hydrostatic examinations, and non-destructive testing strategies. These evaluations are vital for determining potential weaknesses or defects in the materials prior to they are released in real-world applications. Additionally, accreditation by acknowledged companies warranties that suppliers comply with established standards, which fosters trust amongst stakeholders, consisting of end-users, service providers, and designers.

Lots of leading pipeline manufacturers participate in constant surveillance and improvement of their screening protocols to adapt to advancing market requirements and technological innovations. Conformity with standards such as ASTM, ASME, and ISO not just enhances product integrity but likewise lessens the danger of ecological occurrences related to pipeline failures.

Innovative Material Solutions

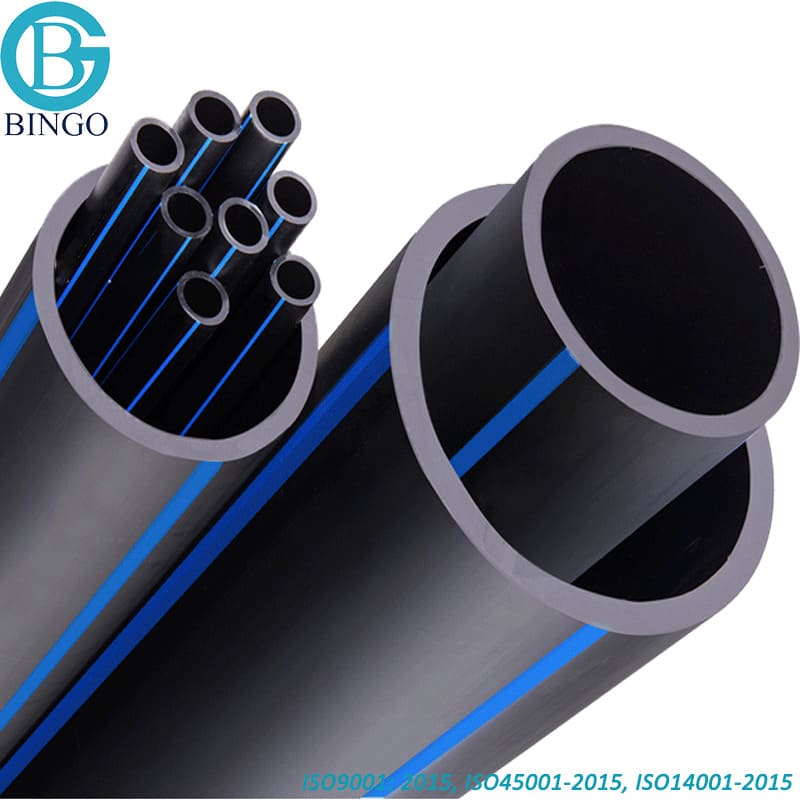

The advancement of ingenious product remedies has transformed the landscape of pipeline manufacturing, improving both efficiency and durability. Advanced products such as high-density polyethylene (HDPE), cross-linked polyethylene (PEX), and composite products have arised as game-changers, supplying superior resistance to corrosion, temperature changes, and pressure variants. American Plastics LLC HDPE Pipeline Manufacturer. These materials not only prolong the life expectancy of pipes however additionally lower maintenance costs, ensuring dependable lasting performance

Sustainability is one more vital emphasis, with manufacturers discovering bio-based composites and recyclable products that reduce ecological impact. As governing criteria remain to progress, the focus on innovative material solutions ends up being vital in meeting strict security and ecological requirements. Eventually, these developments not only enhance the integrity of pipeline systems yet likewise contribute to the overall effectiveness and sustainability of energy transportation facilities.

Innovations in Pipeline Innovation

Technologies in pipeline modern technology are revolutionizing the market by boosting performance, security, and environmental sustainability. Recent improvements concentrate on clever pipeline systems that use sensors and IoT modern technology to keep an eye on conditions in genuine time, enabling proactive maintenance and minimizing the risk of failings. These systems can detect leaks, stress changes, and other anomalies, permitting rapid feedback and reducing ecological impact.

In addition, the advancement of advanced products, such as corrosion-resistant and composite alloys, significantly prolongs the lifespan and dependability of pipes. These products lower maintenance expenses and improve performance in harsh environments, making them optimal for oil, water, and gas transportation.

In addition, automation and robotics are playing an important function in pipeline building and construction and evaluation (Permian Basin HDPE Pipe Supplier). Drones and robotic tools assist in surveys and evaluations of hard-to-reach locations, guaranteeing comprehensive examinations without endangering security

Innovative styles, such as modular pipeline systems, allow for greater adaptability in installation and alteration, providing to the vibrant requirements of the power field. With each other, these technological developments not just improve operational performance but additionally add to a more resilient and lasting pipeline infrastructure, leading the way for a greener future.

Study of Success

Throughout different fields, effective executions of innovative pipeline innovations show considerable improvements in functional effectiveness and safety. One significant instance is the release of wise pipeline surveillance systems in the oil and gas sector, where real-time information analytics have actually reduced leak detection times by over 50%. This not only minimizes environmental risks but additionally enhances the overall stability of pipeline facilities.

One more exemplary situation is found in the water distribution sector, where the installation of innovative products, such as high-density polyethylene (HDPE), has actually brought about a significant decline in pipeline rust and maintenance costs. A major city reported a 30% decrease in water loss because of leakages after upgrading its aging pipeline network with these innovative products.

Furthermore, a major manufacturer executed robotic evaluation technologies in its pipeline upkeep operations, resulting why not find out more in a 40% improvement in evaluation performance. This approach has structured maintenance schedules and considerably minimized downtime.

These situation studies highlight how top pipeline producers are leveraging advanced technologies to promote integrity and operational excellence, ultimately establishing new criteria for the sector (HDPE Pipe Supplier). As these successes continue to unravel, they lead the way for additional developments in pipeline manufacturing and management

Ecological Sustainability Practices

Regularly, pipeline manufacturers are focusing on environmental sustainability methods to minimize their eco-friendly footprint and boost the durability of their items. This dedication is mirrored in numerous efforts targeted at reducing waste, conserving energy, and using lasting products throughout the manufacturing procedure.

Many producers are adopting advanced innovations that lessen exhausts and power usage. The assimilation of automated systems and energy-efficient equipment helps improve production while decreasing dependence on fossil gas. In addition, firms are increasingly transforming to environmentally friendly materials, such as recycled metals and bioplastics, which not only decrease the environmental influence yet additionally advertise a circular economic climate.

Pipeline makers are executing rigorous lifecycle assessments to review the environmental implications of their products from inception to disposal. This technique enables them to recognize chances for renovation and foster accountable sourcing and waste management techniques.

Partnership with ecological companies better improves these efforts, as suppliers seek to align their procedures with global sustainability objectives. Ultimately, these environmental sustainability practices not only add to a healthier earth but additionally position suppliers as responsible leaders in the sector, interesting ecologically aware stakeholders and customers alike.

Future Fads in Pipeline Manufacturing

As the need for much more reliable and sustainable infrastructure grows, pipeline manufacturing is poised for significant innovations that will reshape the industry. Trick patterns expected in the coming years include the assimilation of advanced materials, such as corrosion-resistant and composite alloys, which enhance resilience while reducing ecological influence. Manufacturers are likewise anticipated to adopt ingenious manufacturing strategies, like additive manufacturing and automation, to simplify processes, minimize waste, and reduced costs.

The rise of smart pipeline innovations, including sensing units and IoT tools, will certainly enable real-time monitoring and predictive maintenance, thus enhancing security and functional performance. This electronic makeover will certainly not just maximize resource management but also facilitate compliance with rigid ecological guidelines.

Sustainability will certainly stay a main emphasis, driving manufacturers to purchase environmentally friendly methods, including energy-efficient production approaches and reusing campaigns. As the international focus on climate change increases, pipeline suppliers will certainly need to adapt by creating services that fulfill both economic and ecological demands.

Regularly Asked Concerns

What Industries Mainly Utilize Pipeline Products From These Manufacturers?

Pipeline items are largely made use of in markets such as oil and water, wastewater and gas management, chemical mining, construction, and handling. These fields depend on efficient, sturdy, and risk-free transport of materials and liquids.

Exactly How Do Manufacturers Ensure Conformity With International Pipeline Standards?

Manufacturers ensure compliance with worldwide pipeline standards by applying rigorous top quality control processes, performing regular assessments, sticking to well established regulatory frameworks, and purchasing employee training to promote recognition and understanding of safety and high quality needs.

What Is the Average Life Expectancy of Pipelines From Leading Manufacturers?

The ordinary life expectancy of pipes from leading manufacturers normally varies from 30 to 100 years, depending on product, ecological conditions, and maintenance methods. HDPE Pipe Manufacturing Texas. Regular assessments and adherence to industry requirements considerably influence longevity and performance

Exist Certifications Certain to Pipeline Production Top Quality?

Yes, various accreditations exist for pipeline making quality, including ISO 9001 for top quality monitoring systems and API standards certain to pipelines. These qualifications assure adherence to rigorous security, performance, and ecological standards within the market.

Exactly How Do Manufacturers Take Care Of Pipeline Upkeep and Repairs?

Manufacturers normally apply a proactive maintenance strategy that includes regular assessments, monitoring systems for early detection of issues, and a structured repair work procedure (Pipeline Manufacturer). This technique assurances pipeline stability, reduces downtime, and enhances overall operational efficiency

Quality assessment in pipeline manufacturing pivots on two essential standards: product durability standards and producing process efficiency. Product durability criteria play a vital duty in examining the high quality of pipelines, determining the performance and lifespan of the products utilized in building. The materials and making procedures utilized by pipeline manufacturers play a substantial duty in figuring out the toughness of the final item. The average lifespan of pipes from leading producers generally varies from 30 to 100 years, depending on material, ecological conditions, and upkeep methods. Yes, various qualifications exist for pipeline manufacturing top quality, including ISO 9001 for top quality administration systems and API standards certain to pipes.